Gas Turbine Lube Oil Cooling System

With the compact and reliable construction alfa laval finned coil air heat exchangers ensures optimal heat transfer of the turbine lube oil.

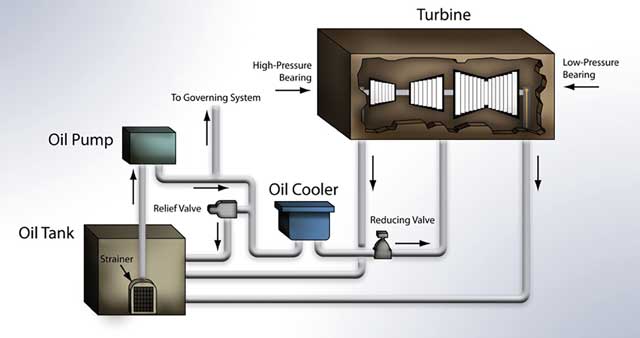

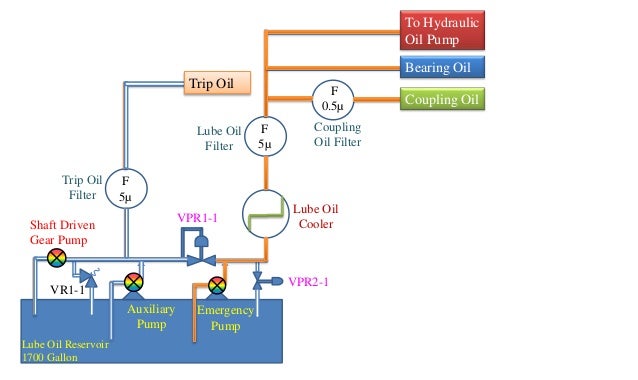

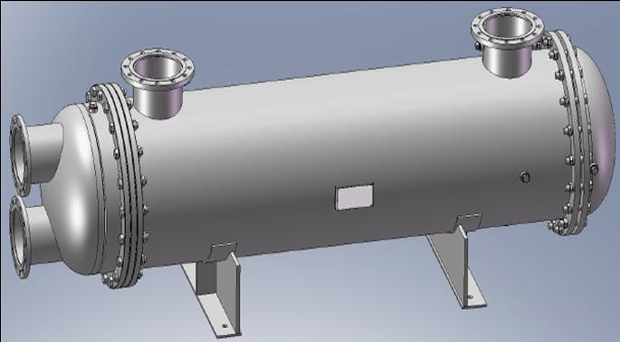

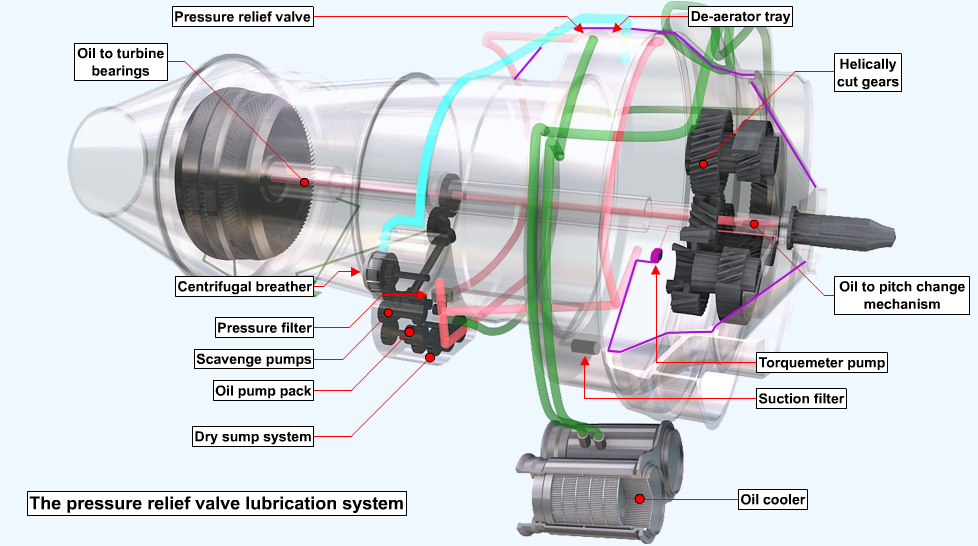

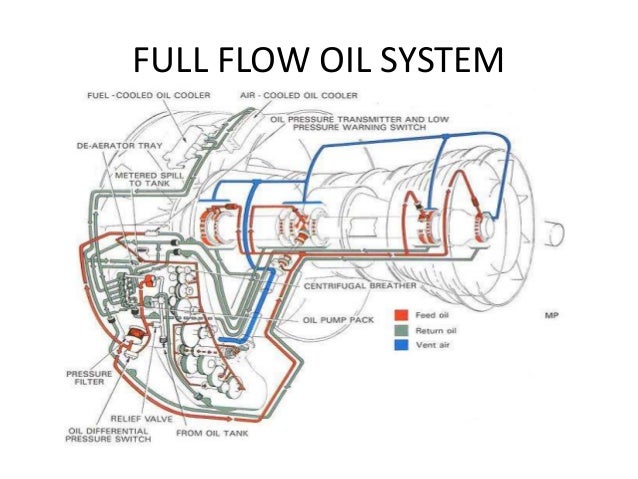

Gas turbine lube oil cooling system. Lube oil cooler performance is impacted by a number of plant specific variables. Coolers are utilized on lubricating oil reservoirs of large rotating equipment to control viscosity and reject heat. The lubrication system usually consists of a large storage tank coolers to remove heat from the oil and pumps to circulate the oil. The system assists in dissipating or settling contaminants providing for temperature fluctuations and storing oil.

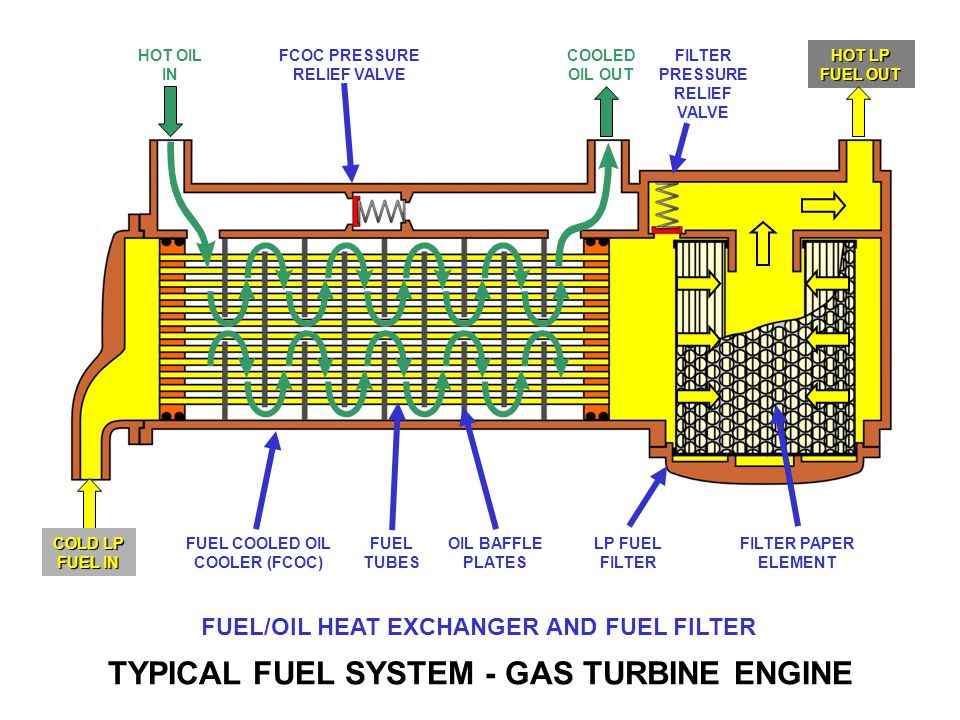

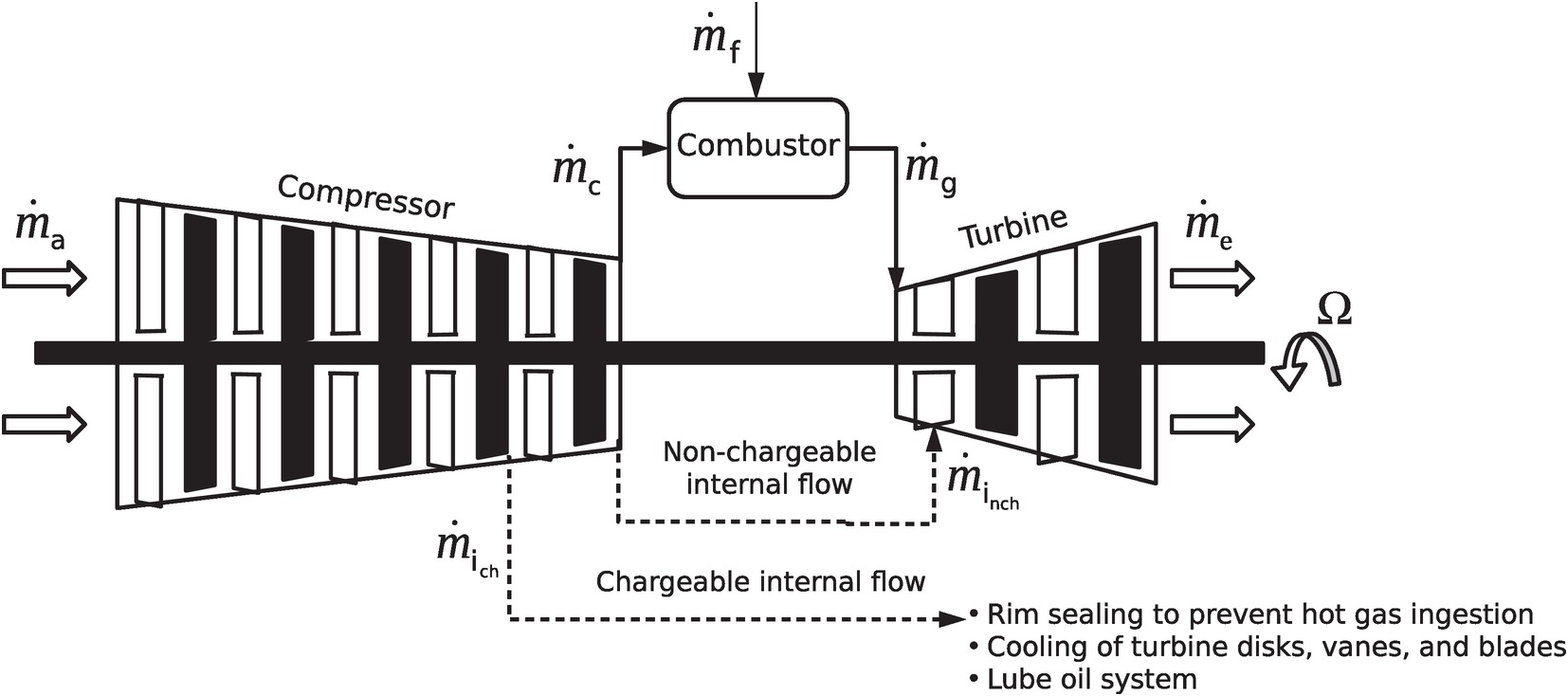

Approximately 48 of the waste heat is in the exhaust stream 27 removed by the lube oil system and 25 removed by the jacket cooling system. Lube oil systems provide lubrication and cooling to gas turbines and other industrial equipment. Gas turbine combined lube and control oil in gas turbine power plants lubrication of the bearings on the turbine shaft main roller journal thrust bearings keeps the turbine running at its optimum. Some applications use synthetic lubricating oil due to its fire resistant property.

The turbine oil is cooled directly in the air heat exchanger. A single lubricating system is usually used for heavy frame gas turbines and driven equipment using mineral oil. In turbomachinery they are important for hydrodynamic bearing performance. Common oils used in these machines have a viscosity of 32 centistokes cst.